The loom is already for weaving. Just need to review my designs, select some colors and away I go.

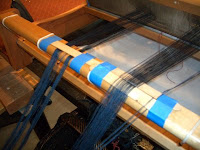

The loom is already for weaving. Just need to review my designs, select some colors and away I go.As you can see, I have two warps so I will get two of everything thing I weave. I will be using two colors which will be common to both pieces and the closure weft color will vary. The pieces will have fringe on both sides so I need a closure weft to keep the warps from shifting around. The closure weft turns on the last warp vs. on the supplementary warp on each side.

There is about 9 yards of warp so this will be quite a production line. I expect this will take perhaps three months to get through. So far I only have one or two designs completed so there will be a lot of designing also.

That warp did stay very neat in that metal contraption. However, going through the reed and heddles did not provide enough tension to keep things straight. It usually does on thicker warp. I kept the leash [popsicle] sticks on the second warp taped to the loom which provided enough tension for that warp. The other warp got a bit twisted. And once there is a twist...it is there for the rest of the warp. Next time I will try to remember to keep them on for both warps.

Now off to the dentist...and then I can design.

No comments:

Post a Comment